Easy Safety Practices for Working on Elevated Surfaces

Working at heights demands diligent planning and vigilant attention to safety details. Whether you’re on a construction site, in a warehouse, or handling maintenance tasks, the inherent risks increase as soon as your feet leave the ground. Establishing reliable protocols and consistently following easy practices can help prevent injuries and protect workers. One essential safety solution is the use of appropriate equipment, such as rolling ladders, which provide stability and ease of movement when working above ground level.

In addition to choosing sturdy equipment, continuously reassessing your environment and refining your habits is critical. Proactive preparation, prompt hazard identification, and adherence to proven safety routines can substantially minimize workplace accidents. These guidelines apply whether tasks are performed outdoors in changing weather or indoors, where clutter and distraction can pose unique hazards.

Falls continue to be a leading cause of serious injuries across many industries. Safe practices are not just regulatory requirements but also vital components of everyday work culture, empowering employees to take control of their own safety and that of their coworkers. Teams that prioritize safety not only reduce the risk of accidents but also achieve higher productivity and stronger workplace morale.

Conduct Thorough Risk Assessments

The cornerstone of accident prevention is a detailed risk assessment preceding any elevated work. Begin by surveying the work zone to identify potential hazards, such as weak or uneven surfaces, overhead power lines, slippery areas, or poor lighting. Each risk you uncover should be weighed, and controls introduced to mitigate it. For example, eliminating unnecessary obstacles, marking danger zones, or selecting a more secure work platform can greatly reduce your risk.

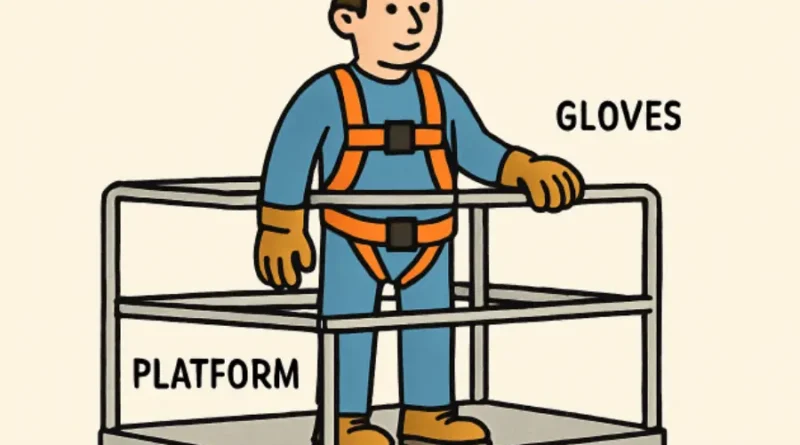

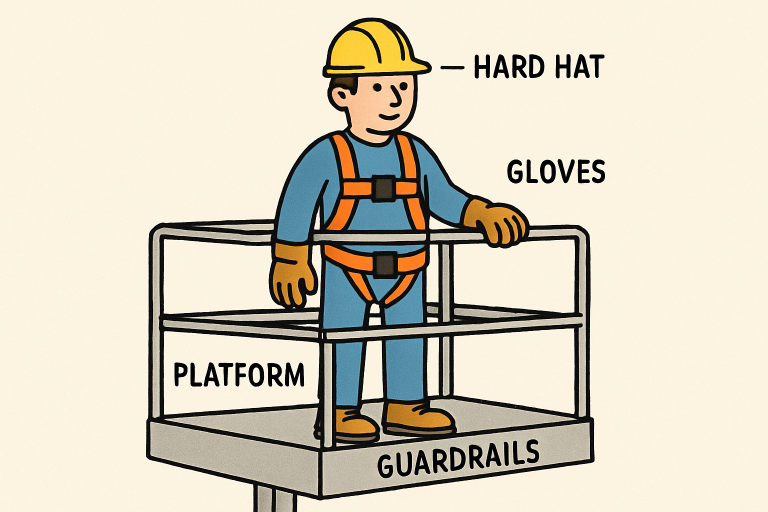

Utilize Appropriate Personal Protective Equipment (PPE)

Wearing the right personal protective equipment is a straightforward yet critical defense against injury. Workers should always wear hard hats to guard against falling tools, gloves to enhance grip and prevent scrapes, and non-slip footwear for traction. Most importantly, anyone working at height should secure a harness that meets current safety standards. Equipment inspections should be performed before each use to spot worn straps, damaged buckles, and signs of corrosion, and to replace anything that does not pass muster. PPE usage should be reinforced with training and checks to ensure ongoing protection.

Maintain Three Points of Contact

Maintaining three points of contact at all times (two hands and one foot, or two feet and one hand) while climbing ladders or scaffolding helps maintain balance and control. This method is especially vital when using portable ladders or ascending fixed ladders with limited support. Workers should avoid carrying tools in their hands while climbing; instead, they should use tool belts or lifting devices to keep their hands free. This practice significantly reduces the risk of slipping, making it much easier to correct a loss of balance.

Ensure Proper Guardrails and Barriers

Guardrails must be installed on all open edges where a fall hazard exists. Industry standards require guardrails to be at least 42 inches high and to include a middle rail and toeboard. The top rail should hold up to 200 pounds without failing to offer dependable fall protection. Toe boards help stop small items from dropping over the edge, safeguarding individuals below. Where guardrails cannot be implemented, consider using safety nets or personal fall arrest systems for additional security.

Regularly Inspect Equipment

Materials such as lanyards, scaffolding parts, harnesses, and barriers deteriorate with regular use. Frequent inspections are necessary to spot signs of damage or unsafe wear. Routine checks should include both visual and tactile inspections, examining buckles, welds, anchor points, and surfaces where corrosion, cuts, or breakage may occur. Any compromised equipment should be repaired or taken out of circulation immediately to prevent preventable accidents on the job site.

Be Cautious of Weather Conditions

Inclement weather can quickly introduce serious risks to those working at elevation. Precipitation, such as rain, snow, or sleet, creates slippery surfaces, while gusty winds can destabilize both workers and materials. If possible, reschedule tasks when hazardous weather is forecasted. If delays are not possible, extra safety precautions should be implemented, such as double-checking anchor points, improving footwear traction, or installing temporary weather shields.

Keep Your Workspace Organized

A crowded work area increases trip hazards and slows evacuation in an emergency. Every tool, cable, and piece of equipment should have a dedicated, secure place. Workers should use tool pouches, bins, and designated storage zones to keep the workspace free of unnecessary clutter. Regular cleanup breaks help maintain order and prevent stray objects from becoming tripping hazards or being knocked from elevated surfaces.

Communicate with Team Members

Strong teamwork and effective communication are foundational to safe work at heights. Reliable information pathways, whether through radios, hand signals, or verbal cues, enable each worker to warn others of hazards or changes in the work environment. Pre-job briefings and safety updates should be routine, with all team members encouraged to report hazards and near-misses promptly, reinforcing a culture of shared responsibility.

Conclusion

Simple, thoughtful safety practices are often the most effective ways to prevent serious accidents on elevated work sites. Conducting risk assessments, wearing appropriate PPE, securing workspaces, and communicating frequently all form a comprehensive safety strategy that can drastically minimize the dangers associated with working above ground.

Visit the rest of the site for more interesting and useful articles.