High Voltage DC Contactors: Advanced Solutions for Modern Power Systems

As renewable energy systems and electric vehicle infrastructure continue to expand globally, the demand for reliable high voltage DC contactors has reached unprecedented levels. These critical components serve as the backbone of modern power distribution systems, enabling safe and efficient control of high-voltage direct current circuits across diverse industrial applications.

Understanding High Voltage DC Contactor Technology

High voltage DC contactors are sophisticated electromechanical switches designed to handle substantial electrical loads while maintaining operational safety. Unlike their AC counterparts, DC contactors face unique challenges due to the continuous nature of direct current, which creates more persistent arcing during switching operations. This fundamental difference necessitates specialized design approaches and materials to ensure reliable performance.

The primary function of these contactors involves making and breaking electrical circuits under load conditions, typically operating at voltages ranging from 12V to 1500V DC. Their robust construction enables them to handle high inrush currents while providing long-term reliability in demanding environments.

Ceramic vs. Resin Construction: Technical Comparison

Modern high voltage DC contactors are available in two primary construction types, each offering distinct advantages for specific applications.

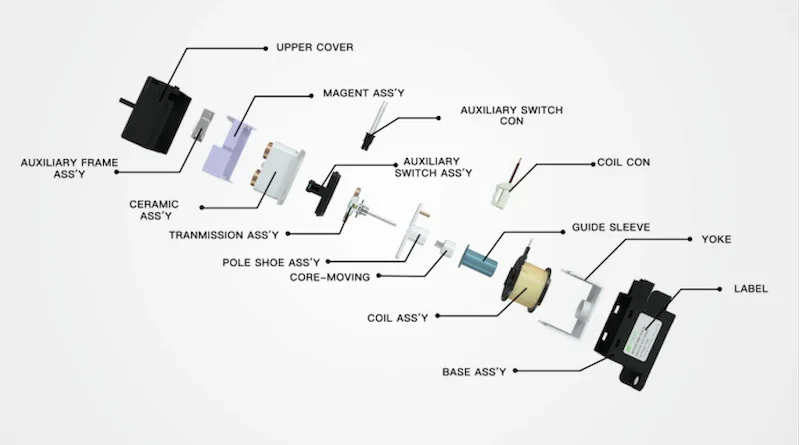

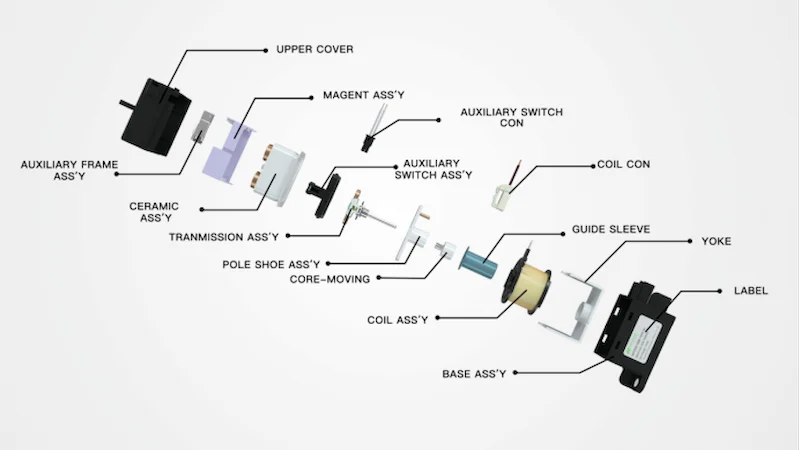

High Voltage DC Contactors (Ceramic)

Ceramic-based contactors utilize advanced ceramic materials for their insulating properties and thermal management capabilities. These units excel in high-temperature environments, offering superior arc extinction properties through their ceramic chamber design. The ceramic construction provides exceptional dielectric strength, making them ideal for applications requiring maximum electrical isolation. Their robust design ensures consistent performance in harsh industrial environments where temperature fluctuations and mechanical stress are common.

The ceramic architecture also enables faster arc extinction during switching operations, reducing contact wear and extending operational lifespan. This makes ceramic contactors particularly suitable for frequent switching applications in renewable energy systems and industrial automation.

High Voltage DC Relays Contactors (Resin)

Resin-encapsulated contactors offer excellent environmental protection through their sealed construction. The resin material provides superior moisture resistance and chemical protection, making these units ideal for outdoor installations and corrosive environments. Their compact design often results in space-saving installations while maintaining high performance standards.

The resin construction also provides excellent vibration resistance, making these contactors suitable for mobile applications such as electric vehicles and railway systems. Additionally, the manufacturing process for resin contactors often results in more cost-effective solutions for high-volume applications.

Critical Applications and Performance Considerations

High voltage DC contactors find extensive use in renewable energy systems, where they manage power flow between solar panels, battery storage systems, and grid connections. In electric vehicle charging infrastructure, these components ensure safe connection and disconnection of high-voltage charging circuits. Industrial applications include motor control systems, welding equipment, and electrochemical processes.

When selecting appropriate contactors, engineers must consider several critical factors:

Current Rating and Voltage Capacity: Proper sizing ensures safe operation without thermal stress or premature failure. The contactor must handle both steady-state currents and transient conditions.

Arc Extinction Capability: Effective arc management prevents contact welding and extends component life. Understanding the fundamental principles of DC contactor operation is crucial for proper application selection.

Environmental Resistance: Operating conditions such as temperature, humidity, and chemical exposure directly impact contactor selection and performance.

Switching Frequency: Applications requiring frequent operation demand contactors designed for extended electrical and mechanical life cycles.

Advanced Features and Integration

Modern high voltage DC contactors incorporate sophisticated features including auxiliary contacts for status indication, built-in surge suppression, and modular mounting systems for simplified installation. Some advanced models include integrated current measurement capabilities and communication interfaces for system monitoring.

The integration of smart features enables predictive maintenance strategies, allowing operators to monitor contact wear, operating temperatures, and switching statistics. This data-driven approach optimizes system reliability while reducing unexpected downtime.

Future Developments and Industry Trends

The evolution of high voltage DC contactor technology continues to address emerging market demands. Manufacturers are developing more compact designs with higher current densities, improved arc extinction technologies, and enhanced environmental protection ratings.

For comprehensive solutions and technical specifications, professional-grade high voltage DC contactors from specialized manufacturers ensure optimal performance across diverse applications.

The increasing adoption of DC power systems in industrial and commercial applications drives continued innovation in contactor technology, promising even more efficient and reliable solutions for future power management challenges.

Conclusion

Both ceramic and resin-sealed High Voltage DC Contactors provide essential switching functionality for modern DC power architectures. Ceramic designs offer maximum robustness and insulation for demanding environments, while resin-sealed contactors balance performance with compactness and cost.

Engineers evaluating EV powertrains, battery storage systems, or industrial automation platforms should assess trade-offs across dielectric strength, thermal stability, weight, and lifetime reliability to select the optimal solution. HIITIO’s portfolio of High Voltage DC Contactors, covering both ceramic and resin-sealed types, is engineered to meet these diverse requirements—offering proven reliability, customizable specifications, and industry-certified safety for mission-critical applications.

Visit the rest of the site for more interesting and useful articles.