How Product Data Management Enhances Compliance in Manufacturing

Manufacturers today face a complex and fast-changing landscape of global regulations, quality standards, and customer expectations. Ensuring compliance is a top priority and a formidable challenge in this environment. Modern manufacturers are turning to Product Data Management (PDM) solutions to centralize information, streamline compliance, and enable efficient, cross-functional collaboration. Leveraging advanced tools such as hosted labeling has become increasingly vital, providing a unified foundation for driving accuracy and visibility across labeling and product documentation workflows.

The ability to manage, monitor, and automate compliance processes not only mitigates regulatory risk but also offers a significant operational advantage. By centralizing the vast array of product data—ranging from technical specifications and material certifications to regulatory declarations —manufacturers can ensure reliable information flow throughout the organization and across the supply chain. This foundation becomes essential when preparing for audits and certifications or responding to ever-evolving market and regulatory demands.

The Role of PDM in Regulatory Compliance

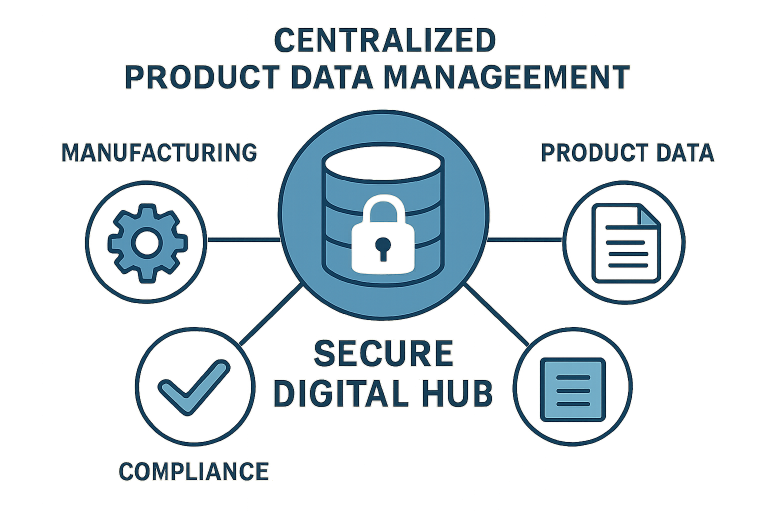

Government agencies and industry regulators impose robust standards to ensure public safety, environmental responsibility, and fair market practices in manufacturing. Adherence to these standards requires a disciplined approach to documenting, storing, and tracking information about products, materials, and testing procedures. A powerful PDM solution serves as a single source of truth, housing critical documentation and compliance records, thereby reducing the chance of errors stemming from departmental silos or obsolete records.

When all your compliance-related data resides within a secure, centrally maintained repository, you minimize the risk of non-compliance and enhance your agility in meeting new requirements. Whether the need is updated labeling, rapid reporting, or instant access to certifications, manufacturers with an advanced PDM system are prepared for scheduled audits and surprise inspections from regulatory authorities.

Proactive compliance through integrated data means a company can quickly identify gaps and resolve issues. This reduces penalties, product recalls, and reputational risk—three of the most costly challenges in manufacturing. Recognizing the role of documentation and traceability, many leading organizations have adopted industry best practices that stress the value of digital transformation in compliance management.

Automating Compliance Processes

Eliminating manual compliance tracking is one of the highest-value benefits of a modern PDM system. By embedding compliance standards directly into workflow and data models, manufacturers can automate real-time monitoring for regulatory changes and ensure continuous documentation updates. This includes everything from new environmental standards to changes in export laws or safety regulations.

For example, suppose the European Union updates its REACH or RoHS directives. In that case, a well-integrated PDM system can automatically notify responsible teams, link relevant compliance documents, and prompt required updates to labeling and certificates. Entire audit trails can be generated with a few clicks, eliminating time-consuming searches and freeing teams to focus on value-added innovation and quality control.

Enhancing Product Traceability

Step-by-step traceability is essential for compliance, especially in industries with stringent quality standards such as automotive, aerospace, electronics, and pharmaceuticals. PDM solutions enable manufacturers to create comprehensive records that track every component, vendor, material, and process associated with a product’s lifecycle. This granular visibility ensures that, if a defect or compliance query arises, the origin and impact of every part can be easily established.

In the event of a recall, you can precisely determine which batches or products are affected, minimizing disruption and risk. The value of such capability cannot be overstated, as rapid response protects brand reputation and is also expected by today’s consumers and regulatory authorities.

Facilitating Collaboration Across Departments

Achieving and maintaining compliance relies on collaboration across engineering, quality control, procurement, and regulatory affairs departments. A centralized PDM system provides every stakeholder access to the most current, validated information, reducing miscommunication and limiting the potential for costly errors. It breaks down information silos, streamlines workflows, and helps ensure consistent application of compliance standards across all departments.

Manufacturers that foster a culture of data-driven collaboration minimize compliance risks and enable a resilient and agile response to internal and external challenges. For additional insights on how manufacturers use integrated solutions to facilitate compliance, visit this informative Forbes article on data transparency.

Real-World Applications of PDM in Compliance

Take, for example, a global manufacturer of electronics for various international markets. By adopting a PDM system, the organization efficiently manages diverse local and global compliance demands, such as environmental, safety, and import/export regulations. The system securely stores multiple certifications, safety data sheets, and regulatory approvals in an easily accessible and auditable format for each product variant, facilitating faster market entry and risk reduction.

Similarly, in heavily regulated industries such as medical devices, centralized PDM enables visibility into every revision and approval of each product, dramatically simplifying preparation for FDA, CE, or other regulatory audits. This digital backbone ensures compliance documentation is always up to date and readily available.

Integrating PDM with Other Systems

Maximum value emerges when PDM is paired with larger enterprise solutions, such as Enterprise Resource Planning (ERP) and Quality Management Systems (QMS). This integrated approach ensures real-time consistency—regulatory updates and compliance data flow seamlessly from the design stage to production, supply chain, and distribution. For instance, synchronizing ERP and PDM means manufacturing schedules or shipments are automatically informed by the latest compliance statuses, minimizing the risk of non-compliant products leaving the facility.

Conclusion

Sustaining compliance in modern manufacturing is no simple task. Still, a robust Product Data Management system makes it possible to proactively manage risk, improve efficiency, and deliver quality products that meet evolving regulatory demands. With the power to centralize data, automate compliance, enhance collaboration, and enable complete traceability, PDM has emerged as an essential competitive resource for manufacturers poised to thrive in the era of global regulation and digital innovation.

Visit the rest of the site for more interesting and useful articles.