Innovative Uses of Bearings in Modern Aircraft

Modern aviation is a story of relentless innovation, and few components exemplify this better than bearings. These seemingly simple elements are critical to the smooth, efficient operation of aircraft, and advancements in their design and application have propelled aviation into a new era of safety, sustainability, and performance. From powering next-generation engines to boosting the capabilities of electric vertical take-off and landing (eVTOL) vehicles, bearings are at the heart of key technological leaps.

Innovative bearing designs now address pressing industry needs such as minimizing fuel use, extending flight range, and streamlining predictive maintenance. Whether it’s the reduction in lubrication requirements for eVTOLs or the integration of real-time sensors into sophisticated flight systems, bearings are driving a new chapter of progress in the aviation sector. As manufacturers look to create both greener and more resilient aircraft, the next generation of bearings is stepping up to meet these evolving demands in critical operational areas.

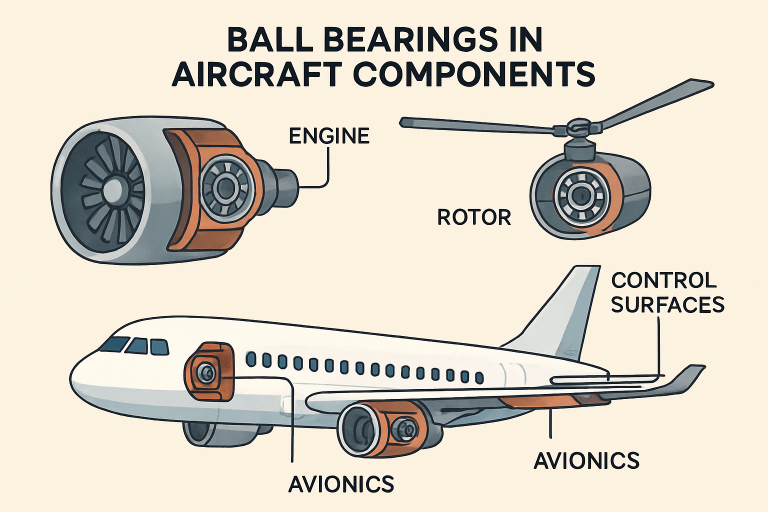

Enhancing Engine Efficiency

As commercial and military aircraft push for greater fuel economy and reliability, advances in bearing technology have become essential. Recent engineering breakthroughs include bearings capable of handling higher rotational speeds with reduced friction and wear. In the hub of innovation, such as aerospace Danbury, CT, engineers and manufacturers continue to refine precision components that enhance aircraft performance and durability. For example, FAG Aerospace produced a ball bearing that can operate at speeds exceeding four million millimeters per minute, directly contributing to lower fuel consumption and higher thrust-to-weight ratios. These innovations support both environmental goals and operational demands, while ensuring compliance with regulatory targets for emissions reduction.

Extending eVTOL Flight Range

The global move toward urban air mobility has placed new emphasis on eVTOL vehicles, which depend on lightweight, efficient bearings for prolonged battery life and increased operational range. NSK’s introduction of a gas turbine generator bearing that lowers lubricant consumption by about 80% is a perfect example of innovation aligned with emerging urban aviation needs. This new bearing technology not only extends flight times but also reduces environmental impact, making eVTOLs a more viable transportation option for congested cities looking to minimize their carbon footprint.

High-Temperature Applications

Aircraft engines routinely operate at extreme temperatures that can compromise conventional bearing materials. To address this, researchers at Texas A&M University engineered high-temperature magnetic bearings that operate reliably above 1,000°F. This capability allows engines to run hotter and more efficiently without risking catastrophic bearing failure, supporting new engine architectures and next-gen airframes.

Flight Control Systems

The precision in aircraft maneuverability depends significantly on the bearings integrated into flight control surfaces. Whether it’s the ailerons, rudders, or elevators, low-torque, high-reliability bearings ensure that these vital components respond accurately to pilot input, even under fluctuating air loads and vibrations. In this context, bearing durability and accuracy are directly tied to both flight safety and the aircraft’s ability to perform complex flight maneuvers.

Avionics and Instrumentation

Highly sensitive navigation systems such as gyroscopes and inertial measurement units (IMUs) depend on miniature precision bearings for optimal operation. The slightest deviation in bearing smoothness can lead to inaccurate data, which, in turn, can negatively affect flight path calculations and overall navigation reliability. As aviation enters an era of increasing automation, the need for flawless bearing performance in avionics becomes even more pronounced. According to NASA, advancements in avionics and instrumentation technologies are critical for achieving higher precision, stability, and safety in next-generation aircraft systems.

These innovations allow aircraft to process data faster, enhancing both situational awareness and real-time decision-making. As aerospace technology continues to evolve, the integration of precision bearings with intelligent avionics will define the next frontier of flight control and navigation excellence.

Sustainable Materials in Bearing Design

The aviation industry remains firmly committed to reducing its ecological footprint, and bearing manufacturers are answering the call with eco-friendly design choices. Innovations include adopting polymer-based bearings and advanced biodegradable lubricants, both of which offer performance comparable to traditional metals but with far less environmental impact. Recent advances also include recycling programs for end-of-life components, supporting a circular economy within the aerospace supply chain and reducing waste at the source.

Smart Bearings with Embedded Sensors

The incorporation of embedded sensors in bearings marks a new frontier in aviation maintenance. These smart bearings can continuously monitor operational conditions such as temperature, vibration, and wear, providing real-time data to ground crews and flight software. This capability enables predictive maintenance strategies, preventing unplanned downtime and enhancing operational safety, while also reducing the total cost of ownership for airlines and military fleets alike.

Conclusion

The rapid pace of bearing innovation is driving progress across the aviation sector, supporting longer flight ranges, greater fuel efficiency, and safer, more sustainable air travel. As advanced materials, intelligent electronics, and eco-friendly processes converge, bearings will remain at the forefront of aerospace engineering—enabling new possibilities in modern aircraft design and performance.

Visit the rest of the site for more interesting and useful articles.