Pipeline Caliper Tool Applications and Industry Trends

Pipeline caliper tools have become indispensable assets in the oil and gas industry, playing a crucial role in maintaining safe, efficient, and compliant pipeline systems. These innovative devices are designed to capture precise measurements of pipeline geometry, identify deformations, and ensure adherence to safety regulations. In recent years, tools for pipeline caliper for accurate diameter and deformation measurement have undergone rapid development, enabling industry professionals to detect irregularities before they escalate into larger issues. The ever-expanding scope of caliper tool applications reflects a broader industry shift toward enhanced safety and data-driven asset management.

Advanced caliper tools now provide detailed insights into pipeline conditions, facilitating proactive maintenance strategies and minimizing downtime. Operators increasingly rely on caliper data to make critical decisions about repairs, upgrades, and regulatory reporting. As regulations tighten and technological capabilities increase, the importance of caliper inspection will only continue to grow, underpinning asset integrity programs across global pipeline infrastructures.

With the importance of maximizing pipeline longevity and averting costly failures, organizations continue to invest in smarter inspection techniques and robust monitoring regimes. Efficient use of these tools not only assures compliance with regulatory bodies but also demonstrates a proactive commitment to environmental stewardship and operational efficiency. The rising trend toward digitized asset management and automated data analysis is set to further amplify the value of modern caliper tool deployments across the sector.

Market research from reputable sources, including Grand View Research, highlights the growing demand for intelligent pipeline integrity solutions as operators confront aging infrastructure and heightened regulatory scrutiny. These market forces are propelling further advancement in tool accuracy, data integration, and user-friendly analytics platforms.

Introduction to Pipeline Caliper Tools

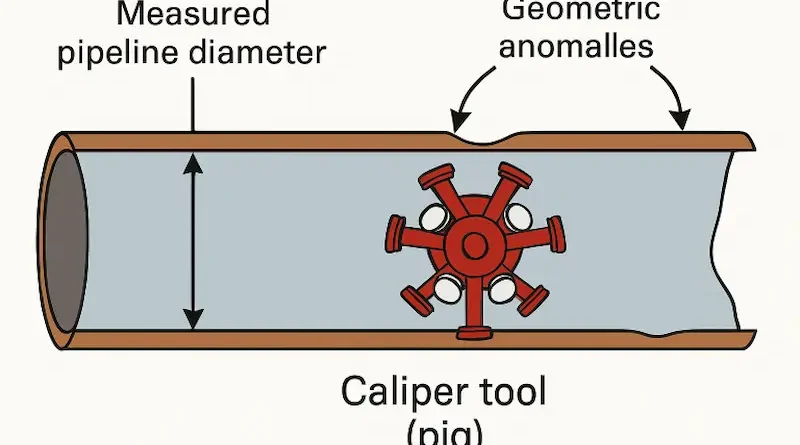

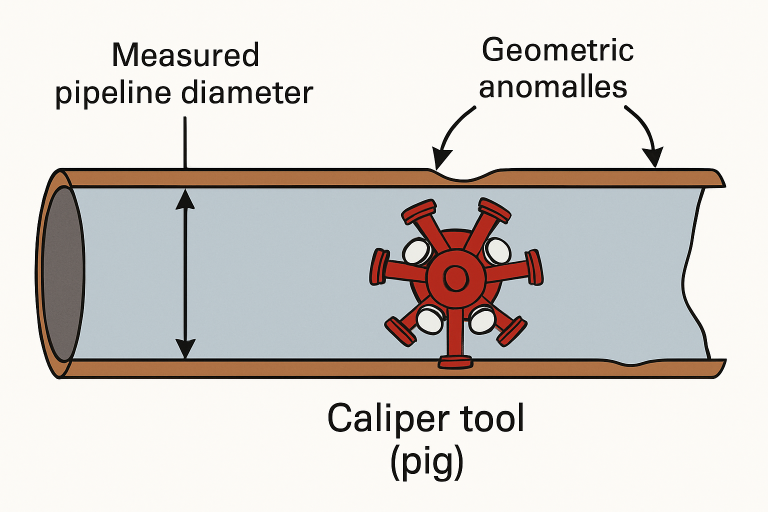

Pipeline caliper tools are specialized inspection devices designed to travel inside pipelines, measuring the internal diameter and identifying geometric anomalies such as dents, ovalities, wrinkles, and buckles. These tools play a crucial role in protecting assets from unplanned failures, enhancing operational safety, and supporting efficient repairs. Their real-time feedback allows operators to prioritize interventions and systematically manage risk across pipeline networks.

Technological Advancements in Caliper Tools

The past decade has seen rapid innovation in the design and capabilities of pipeline caliper tools. Notably, multi-sensor intelligent pigs integrate caliper measurements with technologies such as electromagnetic acoustic transducers (EMAT) and inertial measurement units (IMUs), significantly improving the accuracy and scope of information gathered during a single inspection run. Industry leaders have developed platforms that aggregate high-resolution caliper data with complementary datasets, reducing inspection time and minimizing disruptions to pipeline operations.

Modern tools can now traverse complex pipeline geometries and negotiate smaller diameters, broadening their applicability. Enhanced software platforms automatically analyze collected data and provide actionable reports to operators, significantly expediting decision-making processes and reducing manual interpretation errors.

Applications of Caliper Tools in Pipeline Inspection

Caliper tools are deployed at several critical junctures in a pipeline’s operational lifecycle:

- Commissioning: During the pre-operational phase, caliper runs validate that new pipelines meet engineered specifications and are free from construction-related defects.

- Routine Maintenance: Scheduled or condition-based inspections help track geometric changes over time, facilitating early intervention before anomalies progress to failures.

- Post-Repair Verification: Following repairs or modifications, caliper inspections provide reassurance to operators by confirming the effectiveness of the remedial work and ongoing compliance with technical standards.

Frequent and targeted caliper runs also support asset management initiatives, enabling the optimization of repair schedules and capital allocation based on actual pipeline condition rather than age or theoretical risk. This evidence-based approach reduces unnecessary maintenance activities and focuses attention on areas of highest concern.

Industry Trends and Market Growth

The adoption of intelligent pigging, including advanced caliper tools, has soared in response to aging infrastructure, heightened regulatory scrutiny, and the critical need to prevent catastrophic failures. Recent projections suggest the intelligent pigging market will experience robust growth, with spending expected to rise by approximately USD 228 million from 2024 to 2028, as reported by PR Newswire. Leading operators are embracing IoT-enabled caliper platforms to facilitate real-time data transfer and enable rapid analytics, thereby helping to prioritize risk and streamline compliance management. The drive for digital transformation is making caliper inspection data more accessible and actionable across diverse operational teams.

Regulatory Compliance and Safety Standards

Regulatory bodies worldwide have instituted rigorous standards for pipeline inspection and integrity management. In the U.S., both the Pipeline and Hazardous Materials Safety Administration (PHMSA) and the American Petroleum Institute (API) require detailed inspection records and periodic geometric verification. Caliper tool inspections form the backbone of these compliance efforts, equipping operators with precise, auditable data for reporting and risk assessment. Over time, evolving standards have increased the frequency and detail required for geometric inspections, ensuring ongoing diligence and accountability among operators.

Furthermore, sector-wide adoption of caliper-driven practices reflects the broader industry mandate to minimize environmental risks and protect communities adjacent to pipeline routes. Proactive integrity management, supported by reliable caliper data, helps reduce the incidence of leaks, ruptures, and hazardous spills.

Challenges and Future Outlook

Despite substantial progress, the pipeline industry faces several challenges in maximizing the effectiveness of caliper tools. Difficulties persist in accurately inspecting pipelines with complex geometries, small diameters, or variable internal conditions, such as wax or debris buildup. Another ongoing hurdle is the efficient interpretation of increasingly complex datasets generated by advanced inspection runs. Responding to these challenges, R&D efforts are driving the development of smaller, smarter, and more robust caliper devices, alongside AI-powered data analysis solutions.

The future of caliper tool inspection is closely tied to broader digitalization trends, with cloud-based platforms, machine learning analytics, and sensor miniaturization poised to drive the next wave of efficiency gains. As the global pipeline network ages and operational demands intensify, advanced caliper tools will play a critical role in safeguarding infrastructure and delivering safer, more predictable performance.

Visit the rest of the site for more interesting and useful articles.