Warehouse Storage Solutions and Best Practices for Streamlined Operations

In today’s competitive business environment, warehouse storage is more than just stacking boxes; it’s about optimizing space, accelerating fulfillment, and embracing technology to stay ahead. Whether your warehouse serves a local business or needs to deliver equipment to a facility in Pennsylvania, mastering storage solutions has a direct impact on operational efficiency, cost savings, and customer satisfaction. Streamlining warehouse operations isn’t just a nice-to-have but a necessity for maintaining a responsive supply chain.

The key to an effective warehouse lies in implementing best practices that prioritize efficient space utilization, seamless technology integration, practical worker training, and sustainable operations. Adopting a comprehensive approach ensures you’re not only meeting current needs but also future-proofing your operations against changing market demands.

Optimize Space Utilization

Space is often the most underutilized and costly asset in warehouse management. Maximizing vertical height and intelligently arranging products according to demand increases operational efficiency. Dynamic slotting strategies—where inventory locations are regularly updated as order patterns shift—help minimize travel time and pick errors. For example, storing high-turnover items near pack-out stations simplifies the order fulfillment process. Cross-docking, where inbound goods are directly transferred to outbound transportation without lengthy storage, can dramatically reduce handling costs and inventory on hand. To learn more about maximizing your warehouse footprint, consult advice from established business publications like Forbes.

Implement Advanced Technology

Warehouse efficiency is increasingly driven by integrated technology. Implementing Warehouse Management Systems (WMS), RFID, barcoding, and mobile connectivity enables real-time oversight of products, from receipt to shipment. These solutions boost accuracy and expose potential disruptions before they escalate. Digital twins, for example, are now used by leading warehouse operators to simulate layouts and test workflow optimizations, ensuring every inch of space and second of labor is well spent. Companies equipped with these technologies tend to experience higher throughput and reduced errors, which is essential for enterprises managing complex supply chains.

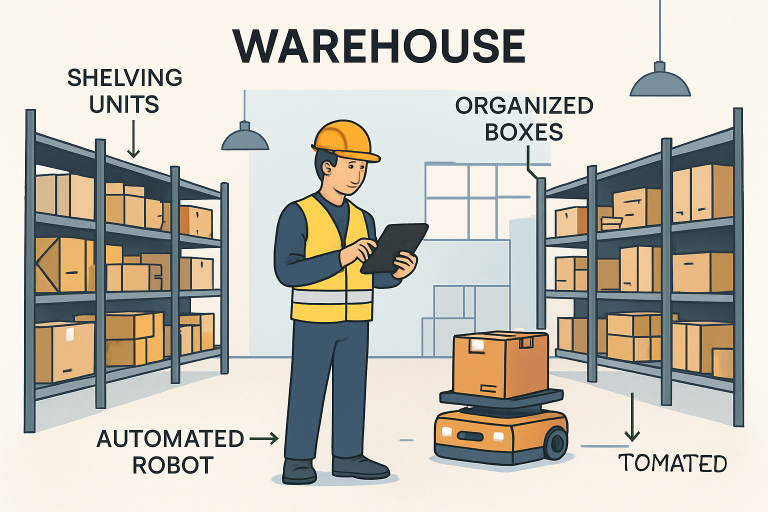

Adopt Automation and Robotics

Modern warehouses benefit from automation that replaces repetitive and error-prone tasks. Automated Mobile Robots (AMRs) autonomously transport goods between stations, while Automated Storage and Retrieval Systems (AS/RS) retrieve items from high-density storage without human intervention. These innovations allow teams to focus on value-added activities and improve safety on the warehouse floor. According to The Wall Street Journal, the adoption of automation can yield improvements in both speed and accuracy, ultimately leading to more resilient warehouse operations.

Enhance Inventory Management

Effective inventory control is crucial for minimizing costs and fulfilling customer promises without overstocking or stock shortages. Apply the First-In-First-Out (FIFO) or Just-In-Time (JIT) method, depending on your product type, to manage expiration, turnover, and demand fluctuations. Leveraging a robust WMS provides real-time inventory visibility and automates replenishment tasks, thereby reducing the risk of manual errors. These systems also help with forecasting, ensuring you avoid tying up capital in excess stock or scrambling to meet unexpected demand spikes.

Focus on Employee Training

The best technology and systems can only take you so far without knowledgeable personnel. Regular, targeted training ensures staff members understand how to use the latest tools, protocols, and equipment properly. Cross-training not only enhances operational flexibility but also keeps workers engaged and ready to step into versatile roles. Employee incentive programs have been shown to improve morale and foster a collaborative culture, which is essential for efficiently handling warehouse peaks.

Prioritize Safety and Compliance

Safety must be a non-negotiable priority in any warehouse. Adhering to local and federal regulations helps prevent accidents, reduce liability, and protect the workforce. Regular audits, safety walk-throughs, and refresher training on proper equipment usage can significantly reduce the risk of injury. Investing in technologies like automated fire suppression systems and environmental sensors demonstrates a proactive commitment to workplace safety.

Integrate Sustainable Practices

Sustainability is now an operational imperative. Implementing energy-efficient lighting, motion-sensor controls, and eco-friendly packaging reduces environmental impact and operating costs. Exploring green energy options, such as solar panels, further aligns business operations with corporate social responsibility commitments. Customers and partners are increasingly choosing suppliers who can demonstrate these values throughout their supply chain processes.

Leverage Data and Analytics

Data is at the heart of continual warehouse improvement. Tracking KPIs, such as order accuracy, inventory turnover, and picking efficiency, allows for the quick identification of bottlenecks and the implementation of quantifiable adjustments. Advanced analytics platforms now aggregate data from various warehouse operations, providing actionable insights that enable more intelligent and faster business decisions. Leveraging these analytics, companies can optimize everything from labor scheduling to space allocation, ensuring long-term competitiveness and profitability. For further insights into deploying warehouse analytics, see resources from Harvard Business Review.

By strategically applying these solutions and best practices, warehouses can create streamlined, productive, and scalable operations that meet future industry demands.