Precision & Progress: Exploring Innovative Approaches to Media Blasting Techniques for Enhanced Surface Preparation

Media blasting, a crucial surface preparation process in industries like automotive, aerospace, construction, and manufacturing, is being rapidly transformed by technological advancements and increased demands for efficiency, worker safety, and environmental responsibility. As regulatory scrutiny and customer demands for higher quality standards increase, integrating next-generation solutions is becoming a necessity. Systems demonstrate how innovation can integrate with traditional processes, yielding more effective, environmentally sound, and economically viable methods. By evolving legacy equipment and embracing digital controls, businesses can tackle modern challenges with precision and sustain success.

Cutting-edge Media Blast solutions now blend the power of automation, sustainable blasting media, and data-driven monitoring. The operational paradigm has been transformed by real-time analytics, automated process adjustments, and scalable setups, resulting in a shift toward smarter, greener, and safer blasting. This has resulted in significant improvements in operational and environmental footprints, with eco-consciousness, robust analytics, and adaptive technology being the foundation for success.

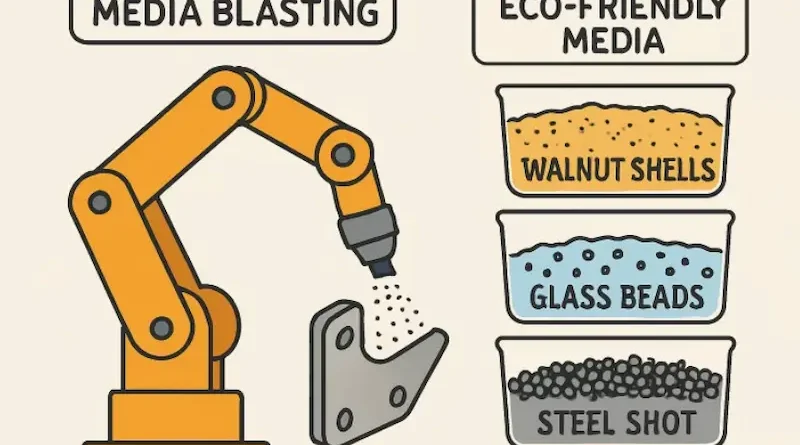

Automation and Robotics Integration

Automation in media blasting is revolutionizing the industry by transforming labor-intensive processes into precision, reliability, and safety models. Advanced robotic arms, powered by artificial intelligence and algorithms, can conduct detailed blasting routines repeatedly without deviation. Sensors monitor motion and contact, ensuring consistency and accuracy. This precision eliminates over-blasting and uneven surfaces, and improves safety by reducing human presence in hazardous environments. Continuous operation makes these systems ideal for high-volume manufacturing, enabling around-the-clock productivity, while standardized operations minimize variability and reduce unexpected costs.

Benefits of Robotic Blasting

- Enhanced repeatability in surface preparation across large batches of components, ensuring every item meets identical quality specifications.

- Substantial reduction of operator fatigue and the potential for mistakes by automating labor-intensive, repetitive tasks.

- Greatly increased workplace safety, helping companies meet or exceed occupational health and safety regulations.

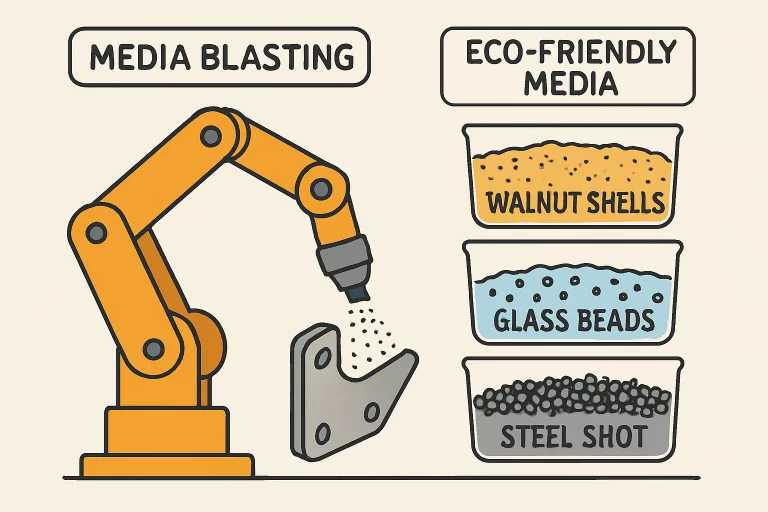

Eco-Friendly Blasting Media

The industry is shifting towards environmentally responsible blasting media, moving away from hazardous materials like silica sand. Innovative alternatives are non-toxic, low-dust, and biodegradable, thereby reducing post-blasting cleanup and waste disposal costs. Recycled abrasives, such as steel shot and glass beads, can be reused multiple times, extending their lifecycle and minimizing resource consumption. Biodegradable materials, such as walnut shells and corn cob granules, provide gentle solutions for restoring delicate and heritage items.

Sustainable Media Options

- Steel shot and grit: Incredibly tough, these abrasives can be recycled dozens of times, making them a favorite for heavy-duty industrial cleaning and peening where longevity is crucial.

- Garnet: A naturally occurring, hard mineral that excels at abrasive blasting; garnet’s non-toxicity and capacity for reuse make it a smart choice for responsible manufacturing environments.

- Walnut shells and corn cob: Organic materials that decompose naturally, these abrasives are particularly well-suited for cleaning soft surfaces—such as in electronics or historical conservation—without polluting the environment.

- Glass beads: Chemically inert and low-dust, glass beads provide a gentle blasting experience while ensuring both operator safety and ecological sustainability.

Digital Monitoring Systems

The digitization of media blasting has revolutionized the industry by enabling real-time data collection and analysis. IoT technology has enabled sensors to monitor all aspects of the blasting process, stream critical information to cloud-based dashboards, allowing immediate adjustments. Proactive alerting systems warn of maintenance needs, reducing breakdowns. Predictive analytics optimize energy use and reduce error risk, conserving resources and ensuring safety. Centralized remote diagnostics simplify troubleshooting, maintenance planning, and compliance reporting for multi-site operations.

- Automated alerts enable crews to schedule maintenance tasks in advance, virtually eliminating unexpected equipment failures.

- Real-time analytics facilitate rapid process improvement by identifying opportunities for optimization in media usage and energy expenditure.

- Remote access and troubleshooting result in fewer travel demands for technical staff and a significant reduction in system downtime across sites.

- Digital logs and documented measurements streamline audits, regulatory reporting, and customer assurance checks, ensuring transparency and accuracy.

Visit the rest of the site for more interesting and useful articles.