How Cutting Technologies Are Revolutionizing Manufacturing Processes

Cutting Technologies: Shaping the Future of Manufacturing

As the backbone of transformation from raw materials to finished products, cutting technology has consistently been at the heart of manufacturing progress. However, introducing advanced techniques and intelligent software has ushered in a new era in recent years. Today’s manufacturers are leveraging these innovations for basic shaping and to streamline entire production lines with greater precision, efficiency, and adaptability. Partners like Bluegrassbit.com are helping companies embrace these changes, ensuring manufacturers remain competitive in a rapidly shifting marketplace.

Industry leaders recognize that staying ahead demands more than incremental change; it requires holistic transformation. The integration of cutting-edge equipment, cloud connectivity, and real-time analytics accelerates growth and enables companies to reimagine their operations. As more factories adopt digital-first strategies, the manufacturing landscape is shaped by versatile solutions that keep pace with evolving consumer and regulatory demands. It’s becoming clear that adopting modern cutting technologies isn’t just best practice—it’s vital for long-term success.

Unmatched Speed and Precision

Pursuing high-speed, high-precision manufacturing has turned advanced cutting methods into essential efficiency drivers. State-of-the-art machines can achieve accuracy within microns, reducing both material waste and the incidence of production errors. In industries such as aerospace, automotive, and electronics, where even minor miscalculations have significant consequences, the demand for precision is paramount. What sets modern cutting technologies apart is their ability to handle intricate geometries effortlessly, facilitating the creation of complex designs that were once considered impossible. By leveraging sophisticated control systems, manufacturers can now deliver consistent, repeatable quality at far greater volumes than before. These capabilities are critical for companies aiming to stand out in competitive global markets.

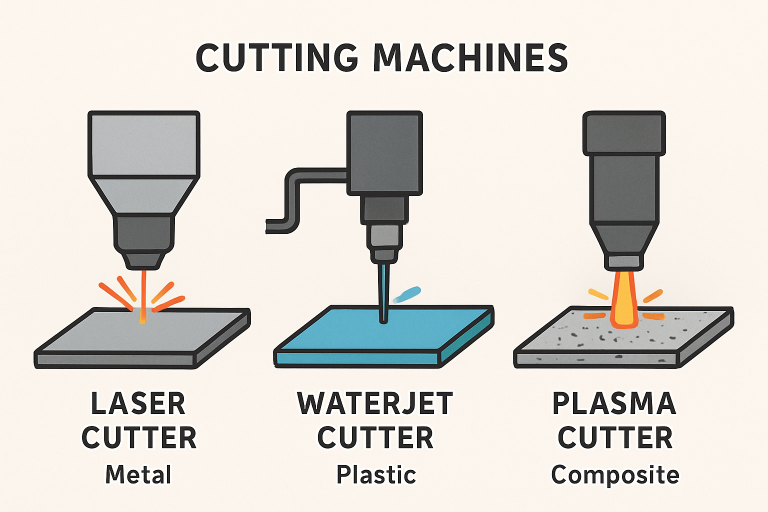

Laser, Waterjet, and Plasma: The Big Players

Three leading technologies—laser, waterjet, and plasma—are reshaping manufacturing across diverse materials and thicknesses. Laser cutting offers unmatched precision and is ideal for metals, plastics, and composites, creating detailed patterns without tool wear. Waterjet cutting, which uses high-pressure streams of water (often combined with abrasive agents), enables cold cutting of heat-sensitive materials, preserving structural integrity without introducing heat-affected zones. Plasma cutting, meanwhile, is prized for its speed and ability to work through thick, conductive metals at a lower cost. The adaptability of these three methods has spurred new applications, as manufacturers benefit from greater versatility and reduced changeover times. The convergence of these technologies with automation will continue to drive productivity gains and quality improvements across the industry.

The Role of Automation and AI

Automation is no longer a luxury reserved for massive manufacturing plants—it’s necessary for businesses striving for consistency, speed, and safety. By incorporating robotics, sensors, and intelligent controls, manufacturers can enable continuous operations and minimize human error. Artificial intelligence amplifies these benefits by optimizing cutting paths, predicting maintenance needs, and ensuring quality assurance through real-time monitoring. Intelligent assistants can now rapidly adjust machine parameters for new job specifications, enabling rapid prototyping and mass customization. As manufacturing facilities integrate these automated solutions, the result is a more innovative, safer, and significantly more productive work environment.

Advancing Sustainability Goals

Sustainable manufacturing is gaining momentum as companies respond to global environmental concerns and regulatory pressures. One of the most impactful changes has been adopting energy-efficient cutting systems that minimize waste and power usage. Technologies that produce minimal heat lessen material distortion and reduce the frequency of scrap, leading to longer product lifecycles. Increasingly, manufacturers use closed-loop systems to capture, filter, and recycle by-products from cutting operations. This aligns with environmental mandates and generates material savings that directly affect the bottom line. Organizations prioritizing sustainability often find themselves positioned as preferred partners for customers with strict green procurement requirements.

Overcoming Challenges in Modern Manufacturing

Despite undeniable progress, implementing advanced cutting technology brings its own set of challenges. Upfront costs can be daunting, especially for small and midsize enterprises. There’s also a learning curve—advanced machinery demands skilled operation and ongoing calibration. Nevertheless, falling prices and more intuitive user interfaces are lowering barriers to entry, even for those without deep technical backgrounds. Companies that swiftly adopt new solutions consistently see improved product quality, reduced lead times, and increased market share. Forward-thinking businesses that proactively tackle these challenges can expect lasting competitive advantages.

Upskilling the Manufacturing Workforce

As high-tech machinery is more central on factory floors, investing in workforce development has never been more critical. Modern operators must be comfortable with hardware and software, mastering everything from CNC programming to automated quality checks. Many manufacturers work directly with vocational programs and technical schools to develop tailored training modules that equip employees with the latest skills. On-the-job learning is augmented by digital resources, enabling workers to upskill quickly and keep pace with technological advancements. A better-trained workforce reduces downtime and operational risk and ensures seamless adoption of the technologies driving the industry forward.

Future Trends in Cutting Technologies

The trajectory of cutting technology points toward even greater automation, digital integration, and flexibility. Developments such as virtual twins and cloud-based data analytics are expected to transform manufacturing plants into hyper-adaptable operations, capable of switching between multiple product types with minimal downtime. Machine learning will become increasingly vital for predictive maintenance, reducing waste and operational disruptions. In this evolving landscape, companies willing to invest in talent, technology, and sustainability will shape the next manufacturing era. By embracing the innovations pioneered by industry leaders, manufacturers can look forward to a future marked by efficiency, adaptability, and responsible production—reinforcing their status as global leaders in an ever-changing world.

Conclusion

Modern cutting technologies are more than just tools—they are catalysts driving global manufacturing efficiency, sustainability, and innovation. These advancements, from precision laser systems to AI-powered automation, empower companies to produce higher-quality products at scale while reducing waste and energy consumption. Though challenges like cost and skill gaps remain, continuous upskilling and adaptive strategies are helping manufacturers bridge those divides. Looking ahead, trends such as digital twins, predictive analytics, and smarter automation will further redefine production capabilities. By embracing these changes today, businesses position themselves not only to stay competitive but to lead the way in shaping the future of manufacturing.

Visit the rest of the site for more interesting and useful articles.