Strip It to Win It: Why a Wire Stripping Machine Pays Off

If you’ve ever wrestled with tangled wires, tedious manual stripping, or ruined cables, you know how frustrating the process can be. Whether you’re a small business owner, an electrician, or a DIY electronics enthusiast, spending hours stripping wires by hand is time-consuming and exhausting. That’s where a wire stripping machine comes in—your new secret weapon for efficiency, precision, and cost savings.

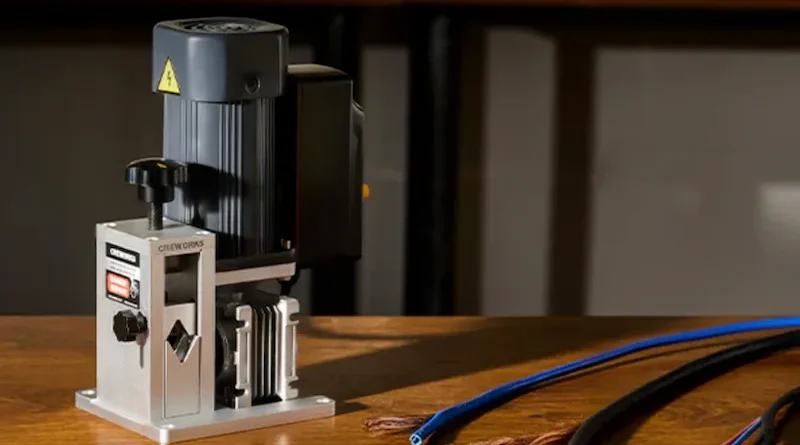

What Is a Wire Stripping Machine?

A wire stripping machine is a tool designed to remove the insulation from electrical wires quickly and accurately. Unlike manual wire strippers, which rely on careful handwork, these machines do the job consistently and with minimal effort.

There are several types of wire stripping machines:

- Manual: Simple, hand-cranked devices suitable for small tasks.

- Semi-automatic: Speeds up the process while still requiring some manual input.

- Fully automatic: Handles high volumes with minimal supervision, perfect for businesses or large projects.

No matter the type, the goal is the same: make wire stripping faster, safer, and more precise.

Key Benefits of Using a Wire Stripping Machine

Time Efficiency

Manual wire stripping can take hours, especially when working with thick or insulated wires. A wire stripping machine can process dozens of wires in the same time it takes to strip just a few by hand. This means faster project completion and more time to focus on other tasks.

Precision and Consistency

Wire stripping machines deliver clean, uniform results every time. This reduces waste from damaged wires and ensures professional-quality finishes, which is particularly important for electricians or businesses that rely on reliable, high-quality connections.

Cost Savings

While a wire stripping machine requires an upfront investment, the long-term savings are significant. You’ll waste less material, save on labor costs, and avoid the expenses associated with errors and damaged wires. Over time, the machine pays for itself.

Safety and Ease of Use

Repeated manual stripping can lead to hand fatigue or even injury. Wire stripping machines reduce strain, making the process safer and more comfortable. Even hobbyists or beginners can quickly learn to operate them effectively.

Who Can Benefit the Most?

- Small businesses that recycle wires or work with electronics regularly.

- Electricians and contractors managing high volumes of wiring.

- DIYers and hobbyists looking for a convenient, reliable solution for electronics projects.

No matter your skill level or volume, a wire stripping machine can make a noticeable difference in your workflow.

Choosing the Right Wire Stripping Machine

When selecting a machine, consider:

- Wire size range: Make sure it can handle the types of wires you use most.

- Automation level: Semi-automatic or fully automatic machines save more time for larger projects.

- Durability and brand reliability: Look for a sturdy, long-lasting machine from a trusted manufacturer.

For consistent performance and reliability, Creworks wire stripping machines are an excellent choice. They’re built for efficiency, handle a wide range of wire sizes, and are trusted by both professionals and hobbyists.

Real-Life Results

Take, for example, a small electronics repair business that upgraded to a semi-automatic wire stripping machine. What used to take hours of painstaking manual labor can now be done in a fraction of the time. The result? Faster project turnaround, happier clients, and reduced material waste—proof that the right tool pays for itself.

Conclusion

Struggling with manual wire stripping is a thing of the past. A wire stripping machine offers speed, precision, safety, and long-term cost savings. Whether you’re running a business, tackling DIY projects, or simply tired of wasted time and effort, investing in one is a smart move.

Visit the rest of the site for more interesting and useful articles.