The Future of Precision Machining in Modern Manufacturing

Introduction to Precision Machining

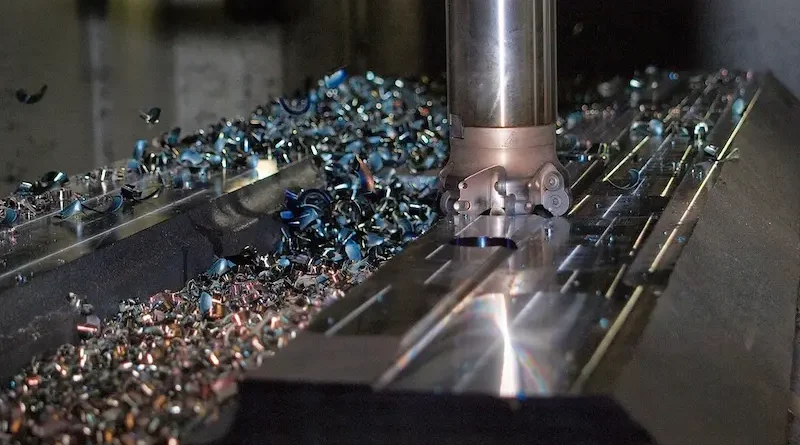

Precision machining is a cornerstone of contemporary manufacturing, bridging the gap between raw concepts and finished products with high accuracy and minimal tolerances. It represents the sophisticated art of crafting components that fulfill intricate specifications. As industries shift towards more complex product requirements, technologies such as CNC Milling are becoming increasingly indispensable. This technology enables manufacturers to achieve unparalleled levels of precision in production, ensuring uniform quality on a large scale.

The reach of precision machining extends across various sectors—from automotive to aerospace, electronics, and even healthcare. This technique not only boosts production efficiency but also helps meet the high standards of product quality and durability expected in the 21st century. As manufacturing continues to evolve, the reliance on precision machining is expected to grow, driven by the consistent demand for excellence in production.

Technological Advancements Driving Precision Machining

The last few decades have seen substantial advances in precision machining, propelled mainly by technology. The emergence of robots and computer numerical control (CNC) machinery has revolutionized the manufacturing of parts by creating an atmosphere in which accuracy is not just feasible but assured. These technologies permit the crafting of intricate designs with exceptional ease and precision, ruling out the inconsistencies associated with manual machining.

Further fuelled by artificial intelligence, these systems are set to automate more aspects of manufacturing processes, optimizing time and reducing human error. IndustryWeek notes that such technologies are integral in today’s smart manufacturing setup, providing a competitive edge to those who adopt them. Embracing these tools is not optional but a requisite for manufacturers who wish to remain at the forefront of innovation and efficiency.

Key Benefits of Precision Machining

- Improved Accuracy and Consistency: Precision machining’s core advantage is its ability to produce components with minimal variability. This guarantees that every element satisfies the precise requirements, which is especially important in sectors where even little deviations can cause serious problems.

- Increased Efficiency and Lower Production Costs: Precision machining reduces the time and material wasted during production, enabling manufacturers to keep costs low while maximizing output. This increase in efficiency translates directly to better profit margins.

- Flexibility in Design and Material Usage: Advanced machining techniques allow manufacturers to experiment with various materials and complex geometries without sacrificing precision, fostering innovation in product development.

- Higher Quality Products: Components produced through precision machining are often more durable and perform better, leading to end products that exceed consumer expectations regarding reliability and life span.

These advantages highlight why precision machining is preferred for industries seeking high-quality, cost-effective manufacturing solutions. It meets the market’s current demands and prepares manufacturers for future challenges.

Applications of Precision Machining

The versatility of precision machining means it is applied in a diverse range of industries. In aerospace, precision is paramount to ensure that components like turbine blades and airframe structures can withstand extreme conditions. Automotive manufacturers depend on this technology to fabricate engine parts and systems that require exact specifications for functionality and safety.

Circuit boards and connectors are two examples of electronic components that benefit from the accuracy that precision machining provides. The medical field also uses these capabilities, crafting precise surgical tools and implants for enhanced patient outcomes. The far-reaching applications of precision machining emphasize its critical role in advancing industrial capabilities and innovations.

Sustainability and Precision Machining

Precision machining is no exception as global industries shift towards more sustainable practices. It has adapted by minimizing waste and optimizing material usage, directly contributing to reduced environmental impacts. By enhancing the efficiency of its processes, precision machining ensures energy consumption is kept at a minimum.

These sustainable practices help lower manufacturing’s environmental footprint and support businesses by reducing operational costs. Precision machining, therefore, is a key player in the push for environmentally responsible production, aligning with broader global sustainability initiatives.

Challenges and Solutions in Precision Machining

Despite its numerous benefits, precision machining faces challenges such as high initial capital investment for advanced machinery and a shortage of skilled labor. These hurdles can be daunting, especially for small and medium-sized enterprises looking to compete in the market.

Nevertheless, various strategies are being deployed to address these challenges. Training programs and apprenticeships are rising, providing the skills needed to operate sophisticated machines. Companies are also turning to technology, as highlighted in Manufacturing.net, to streamline processes and reduce costs. By creating a more competent workforce and democratizing access to modern manufacturing capabilities, these solutions open the door for a wider use of precision machining technologies.

Future Trends in the Precision Machining Industry

The future of precision machining aligns closely with the ongoing development of innovative manufacturing ecosystems. The growing prevalence of IoT integration in manufacturing equipment leads to more intelligent, more connected production processes. This transition to smart factories enhances operational efficiency and reduces downtime through predictive maintenance.

Moreover, the advent of simulation software allows manufacturers to test designs virtually, minimizing the need for costly physical prototypes. As these trends gain traction, precision machining will become more efficient and more adaptive to the changing needs of industries worldwide.

How To Choose the Right Machining Partner

Selecting the right machining partner is crucial for businesses that leverage precision machining’s advantages. It involves carefully evaluating several factors, including a potential partner’s technical capabilities and industry experience. A robust reputation for quality and reliability is also key to ensuring that your production needs are met efficiently.

Additionally, assessing a partner’s customer support level and innovation capacity can make a significant difference. Considering these factors will result in a successful collaboration that supports and improves your manufacturing processes and lays a strong basis for future expansion and innovation.