Damping Hinges for Commercial Use: Benefits and Applications

Companies that make hinges know that whenever a user opens or moves a device with a hinge, they are both exerting force and experiencing a distinctive tactile experience. With positioning hinge technology now available, industrial designers have various options to improve both experiences. Damping hinges, also known as constant torque hinges, is one example. They offer smooth, intuitive movement and eliminate slamming that can lead to health and safety issues.

Benefits

Whether it’s the simple act of opening and lowering a tray table on an airplane or gently adjusting a credit card reader device at checkout, users engage with hinged devices daily. These touch points affect the user experience and create impressions about the product. Hinge manufacturers now offer positioning technology that allows industrial designers to define and adjust operating efforts to position or open a door, compartment, or other mounted device. Damping hinges allow the force required to move a hinged device from a closed to an open position to be factory-set. This will enable users to intuitively move a device by applying the desired amount of effort, giving the hinged device a sense of solidity that can enhance the perception of quality. These patented positioning hinges also provide asymmetric torque by adjusting the effort required to move the hinged device in one direction instead of the other.

Applications

Whether tilting and lowering a tray table on an airplane or slightly adjusting a credit card terminal at the checkout counter, users take thousands of touch points with devices that depend on positioning hinges. Working through the total usage cases – what ergonomic effort should be expended to open, position, and close the device and what user feedback is needed or desired – helps designers cost-effectively configure the right positioning technology for each application. Commercial continuous hinges automatically disperse the pressure of repeatedly opening and closing a door, providing extreme uniform strength along their entire length and generating a pivot action that’s smooth and steady. They can also be crafted to prevent hardware exposure and repel acids, caustic chemicals, and other hostile environments. Most continuous hinge varieties feature an elongated slot or notch punched near the end of the hinge arm that mates with a hole located on the mounting plate. Loosening the fixing screw on the mounting plate enables you to change the depth of the hinge, with some designs offering a range of 3 to 5 mm of movement.

Design Considerations

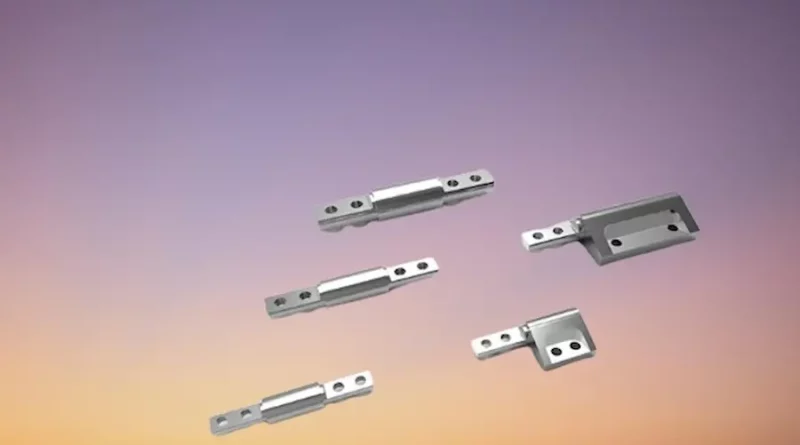

Hinges are available in various styles and configurations to support specific ergonomic requirements. Designers must understand the usage case — what effort should be expended to open, position, and close a device, what user feedback is desired, and how often the hinge will be used. Leading hinge suppliers have extensive experience working through these usage cases to help design engineers choose the right positioning technology. Detent hinges — also called friction or constant torque hinges — keep devices in a fixed, static position until acted upon by force. They’re ideal for doors, access panels, and lids that must remain open at a certain angle to facilitate entry or avoid collision with equipment or machinery. For concealed hinges that mount to the backside of a door, the thickness of the mounting plate determines the amount of overlay the hinge creates. Typical manufacturer standards for this measurement can vary, so designers should review datasheets to select the correct mounting plate thickness and hinge crank size to achieve the desired overlay.

Maintenance

Every time an end user opens, closes, or moves a hinged device, they’re exerting force and experiencing a unique feel to the hinge. Positioning hinge technology now gives designers the tools to control that experience. For example, a tray table that flops down after opening can lead an airline passenger to question the quality of the flight. But with a constant torque hinge with a factory-set resistance level, engineers can design the device so that it lands gently. Other commercial hinges are designed to distribute the applied force rather than relying on a single point of contact for opening and closing. Continuous or piano hinges are fabricated in materials that resist wear and environmental conditions. For example, they’re often made from aluminum or stainless steel to resist corrosion. Other commercial hinges feature a plastic or wood material for shimming that’s easier to cut and won’t swell or break down in damp locations.